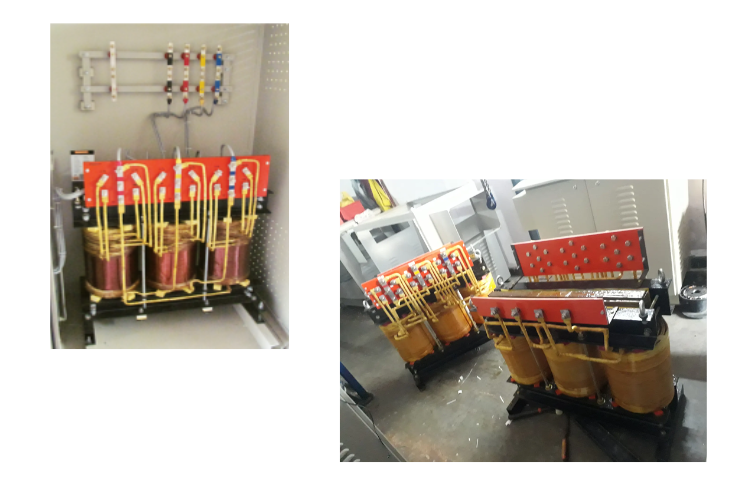

Om Make K-Rated Transformers are specially designed to with stand this Harmonic non-linear load K-rating differs according to the harmonic levels like K-1, K-4, K-7, K-13, K-20, K-30, K-40, K- factor is defined as a ratio between the harmonic & eddy current losses at 50Hz / 60Hz It is used to determine how much non-linear Harmonic load / current can with stand transformer to without exceeding it maximum temperature level.

The noise Isolation transformer Suppresses common mode noise by introducing a grounded shield between its primary and secondary windings. The grounding shield provide also impendence path to ground by capacitive coupling which prevents unwanted high frequency signals contained in the source voltage form reaching the Transformer secondary.

Application : Data centers, IPO centers, UPS, VFD & drives, Hospitals Medical Centers, Research Lab, Corporate Bank Offices, Shopping Malls

Electrolytic grade copper winding, coil designing of high harmonic

current carrying & low eddy current losses. We are using high grade (CRGO) 0.23 to 0.27 notching type of lamination which can only prevent core saturation due to non-linear harmonic, working with good flux densities to compensate for harmonic voltage distortion high thermal with stand capacity class "H"insulation multi shielded transformer where you will gate higher common mode noise attenuating and 100% linear harmonic attenuation and more than 75% non-linear loads low temperature rise.

We are designing our 'K' Rated Transformer according to its guideline specification given by UL1567, ANSIC57, IEEE-519-1981. 'K' Rated recommendation given by ANSI Standard. CE approved.

OM Industries DC Power Supplies durability and performance maximize end-user productivity and minimize downtime.

OM Industries manufactures a complete line of Industrial DC Power Supplies (rectifiers) for

e-coating, plating, anodizing, and other applications requiring DC power. We offer the

industry's highest quality rectifiers, apitalizing on over 25 years of expertise. This quality is

reflected in the design, material, workmanship, and operating performance of each rectifier

we build.

In addition to a quality product, our staff of experienced design and application engineers is

one of the very best reasons to choose a OM INDUSTRIES rectifier. Our expertise extends into

software and PLC programming which offers a significant benefit to the OEM and

end users.

Each of our rectifiers is available in

air or oil cooled configurations, as well as modular and

non - modular configurations. We also specialize in

custom designs.